What Refractory Materials Are Commonly Used In Cement Kilns

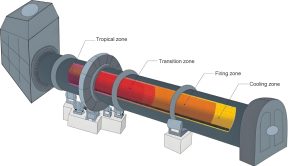

478Cement kiln is the hot work for producing cement clinker, commonly used are vertical kiln and reversing kiln. Vertical kilns are characterized by simple equipment, low investment and high thermal efficiency, but the quality of calcined clinker is...

View details Chunlei Rotary kiln

Chunlei Rotary kiln